-40%

Stainless Steel Compression Tube Ball Valve - 1/8'', 1/4'', 3/8'' - Straight

$ 24.28

- Description

- Size Guide

Description

Ball Valve:Ball valves use a spherical disc to control the flow between pipes, tubes, or hoses. Flow is allowed when the hole that pierces the ball-shaped disc is in line with the inlet and outlet of the valve. Flow is blocked when the ball is horizontally swiveled 90 degrees, so that the hole of the ball is perpendicular to the opening of the valve. Ball valves can be referred to as full port or reduced port (also known as regular or standard port) depending on the inner diameter of the valve.

A ball valve is full port if the hole of the ball is the same size as the inner diameter of the connecting pipeline (resulting in lower friction) and is reduced port if the hole of the valve is one pipe size smaller than the pipe, resulting in less flow through the valve than through the shaft of the pipe. Ball valves may have a handle or lever that aligns with the ball's position (open or closed) for manual operation. They are primarily used in air, gas, liquid, and steam applications.

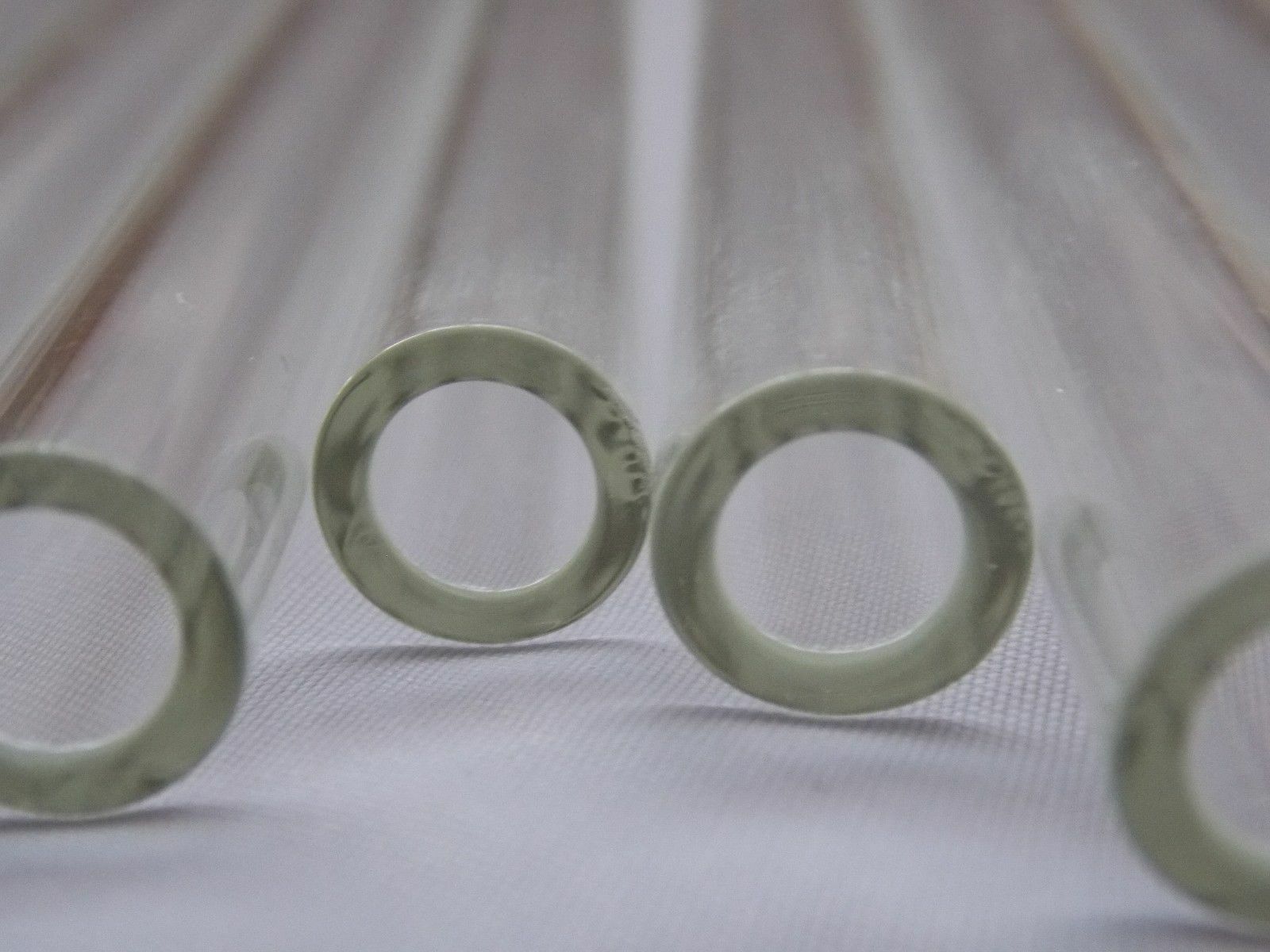

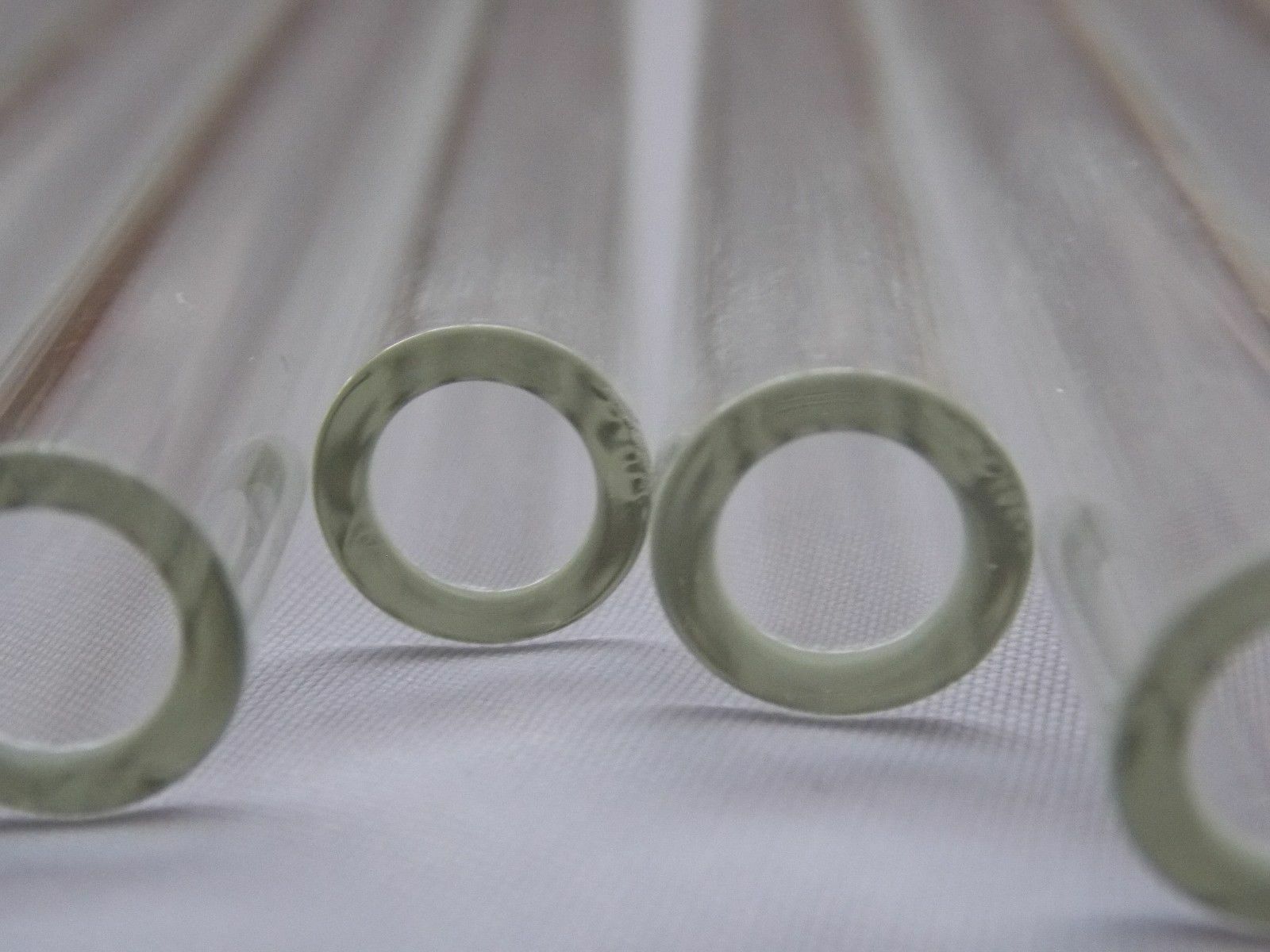

Compression fitting:

The compression fitting is composed of an outer compression nut and an inner compression ring or ferrule (sometimes referred to as an "olive"). Ferrules vary in shape and material but are most commonly in the shape of a ring with beveled edges. To work properly, the ferrule must be oriented correctly?usually the ferrule is fitted such that the longest sloping face of the ferrule faces away from the nut. When the nut is tightened, the ferrule is compressed between the nut and the receiving fitting; the ends of the ferrule are clamped around the pipe, and the middle of the ferrule bows away from the pipe, making the ferrule effectively thicker. The result is that the ferrule seals the space between the pipe, nut, and receiving fitting, thereby forming a tight joint.